Automatic Multi-bags Box Packaging Machine

Technical Parameter:

| Model | CSZ-130 |

| Packing speed | 30-80cartons/min |

| Size of package | L(90-260)mm×W(60-130)mm×H(30-90)mm |

| Cardboard material | 250-450g/㎡ |

| Instruction material | 60-70g/㎡ |

| Instruction size (Unfold) | (80-150) x (90-170)mm |

| Instruction size (Fold) | (1-4) Fold |

| Motor power | 1.5kw |

| Power supply | 380V 50HZ or 220V 50HZ |

| Minimum Air pressure | 0.5-0.8 Mpa |

| Air consumption | 120-160L/min |

| Maximum noise | 80dB |

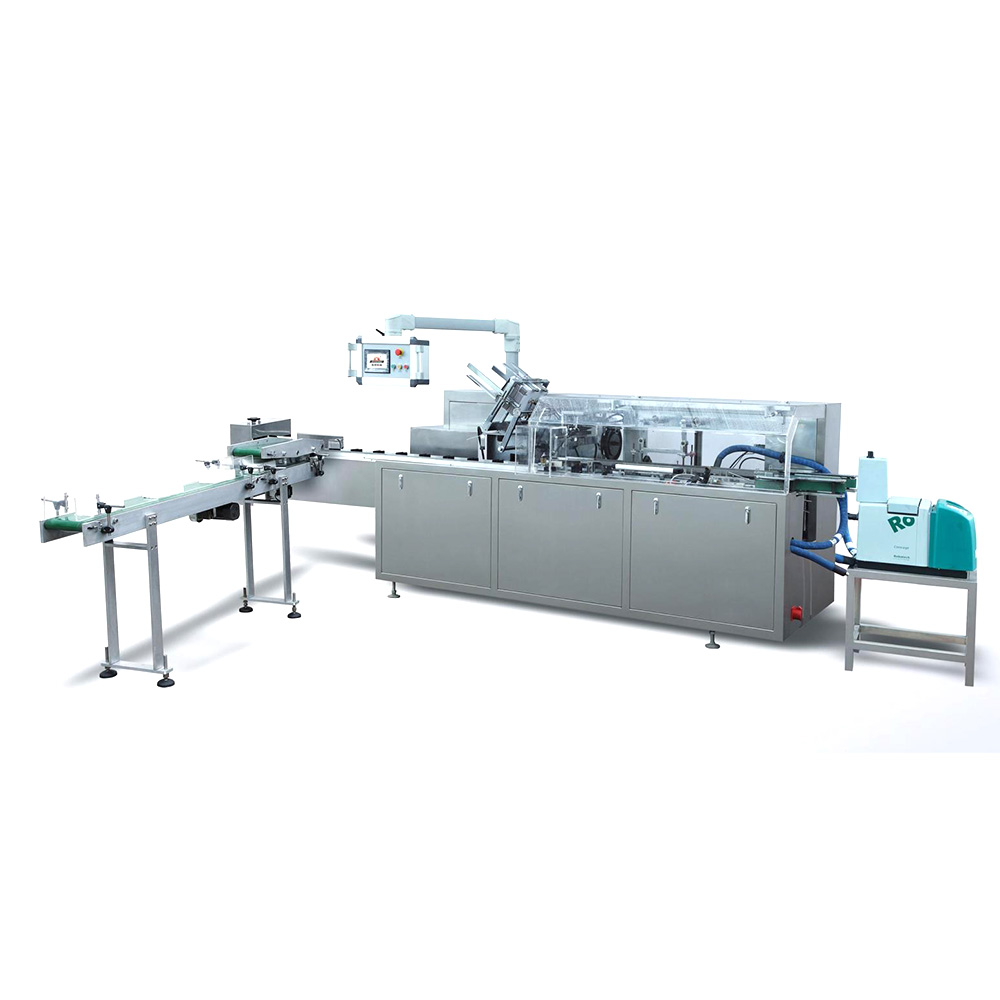

| Overall dimension | L3800mm×W1350mm×H1900mm |

| Weight | 1500Kg |

Electric Configuration:

| PLC | CPIE-N30DT-D/Omron |

| PLC Extened Module | CPIE-C1F11/Omron |

| Touch Screen | NB7W-TW00B/Omron |

| Sensor | E3Z-D61/Sick |

| Frequency | 3G3JZ-A4015/Omron |

| Relay | MY2 NJ24V/Omron |

| Button | XB2/Schneider |

| Emergency Stop | ZB2 BC4D/Schneider |

| Electromagnetic Valve | 4V210-08/Airtac |

| Pressure Regulator Valve | BFR-2000/Airtac |

| Proximity Switch | TL-Q5MC1/Omron |

| AC contactor | LC1E3210M5N/Schneider |

| Air switch | 3P32A 1P6A/Schneider |

| Vaccum Sounder | ABM20-C/SMC |

Machine introduction:

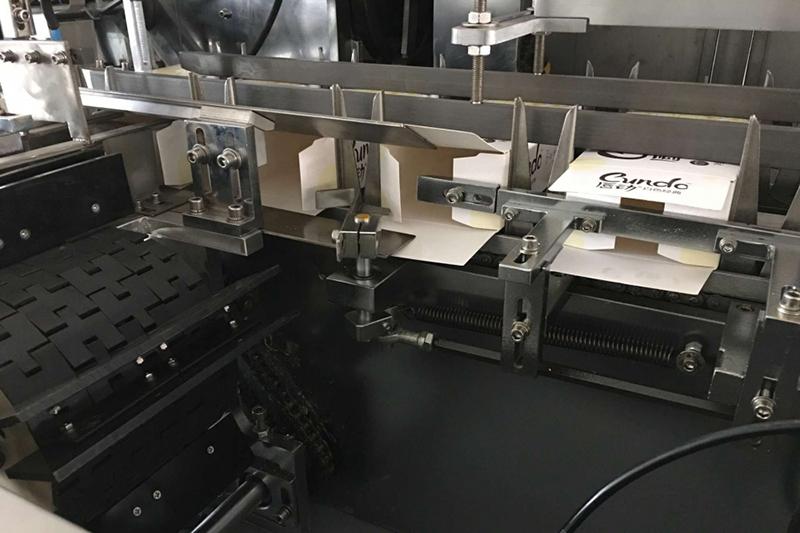

This machine can be easily adjusted to meet the specific needs of each customer by changing the molds, allowing for quick and efficient product changes. It is well-suited for large-scale production of a single product type or multiple small products. The installation and debugging process is simple, and it can be used as a standalone machine or integrated into a larger production line with other devices such as blister packer and hot melt glue machine.

Machine Features:

1.User-friendly touch screen interface for easy operation and control.

2.High-performance PLC programming for reliable and efficient machine automation.

3.Integration of top-quality Omron electric parts from Japan, including inverters, PLCs, and touch screens.

4.Incorporation of precise and durable Sick photocells from Germany.

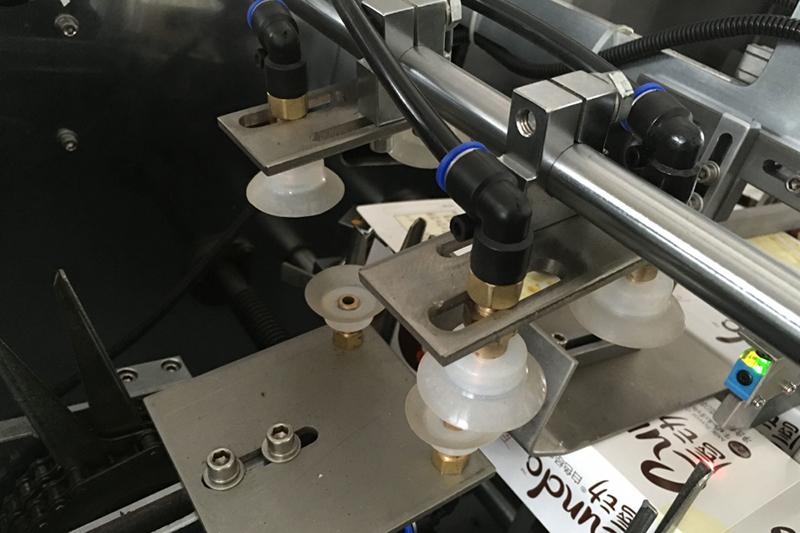

5.Vacuum-assisted pre-break for improved production efficiency and product quality.

6.Versatile machine sizing options to suit various production needs and to facilitate integration with existing production lines.

7.Incorporation of automatic carton suction system to ensure proper handling of products.

8.Automatic display of machine issues, alarms, and finished product counts for easy monitoring and maintenance.

9.Overload protection feature to ensure safe and reliable operation.

Detailed Pictures: