Biscuit Carton Box Packaging Machine

Technical Parameter:

| Model | CSZ-200 |

| Packing speed | 30-80cartons/min |

| Size of package | L(70-350)mm×W(80-200)mm×H(20-90)mm |

| Cardboard material | 250-450g/㎡ |

| Instruction material | 60-70g/㎡ |

| Instruction size (Unfold) | (80-150) x (90-170)mm |

| Instruction size (Fold) | (1-4) Fold |

| Motor power | 1.5kw |

| Power supply | 380V 50HZ or 220V 50HZ |

| Minimum Air pressure | 0.5-0.8 Mpa |

| Air consumption | 120-160L/min |

| Maximum noise | 80dB |

| Overall dimension | L4200mm×W1350mm×H1900mm |

| Weight | 1500Kg |

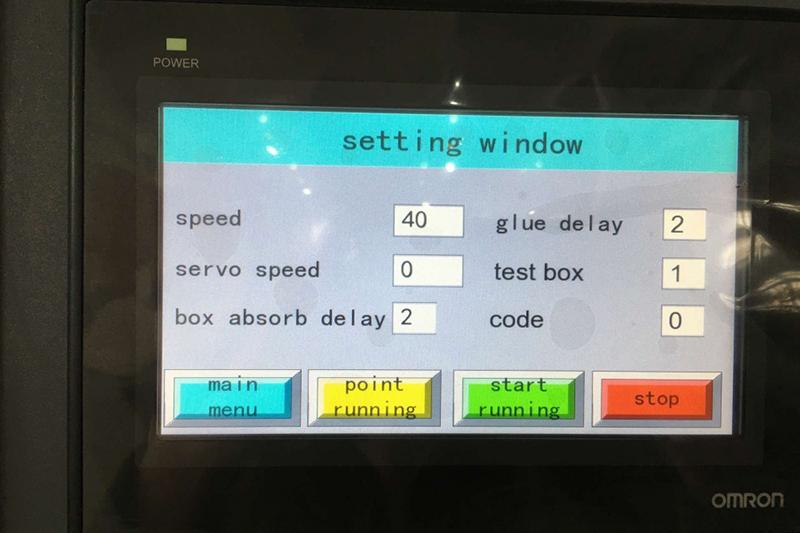

| PLC | CPIE-N30DT-D/Omron |

| PLC Extened Module | CPIE-C1F11/Omron |

| Touch Screen | NB7W-TW00B/Omron |

| Sensor | E3Z-D61/Sick |

| Frequency | 3G3JZ-A4015/Omron |

| Relay | MY2 NJ24V/Omron |

| Button | XB2/Schneider |

| Emergency Stop | ZB2 BC4D/Schneider |

| Electromagnetic Valve | 4V210-08/Airtac |

| Pressure Regulator Valve | BFR-2000/Airtac |

| Proximity Switch | TL-Q5MC1/Omron |

| AC contactor | LC1E3210M5N/Schneider |

| Air switch | 3P32A 1P6A/Schneider |

| Vaccum Sounder | ABM20-C/SMC |

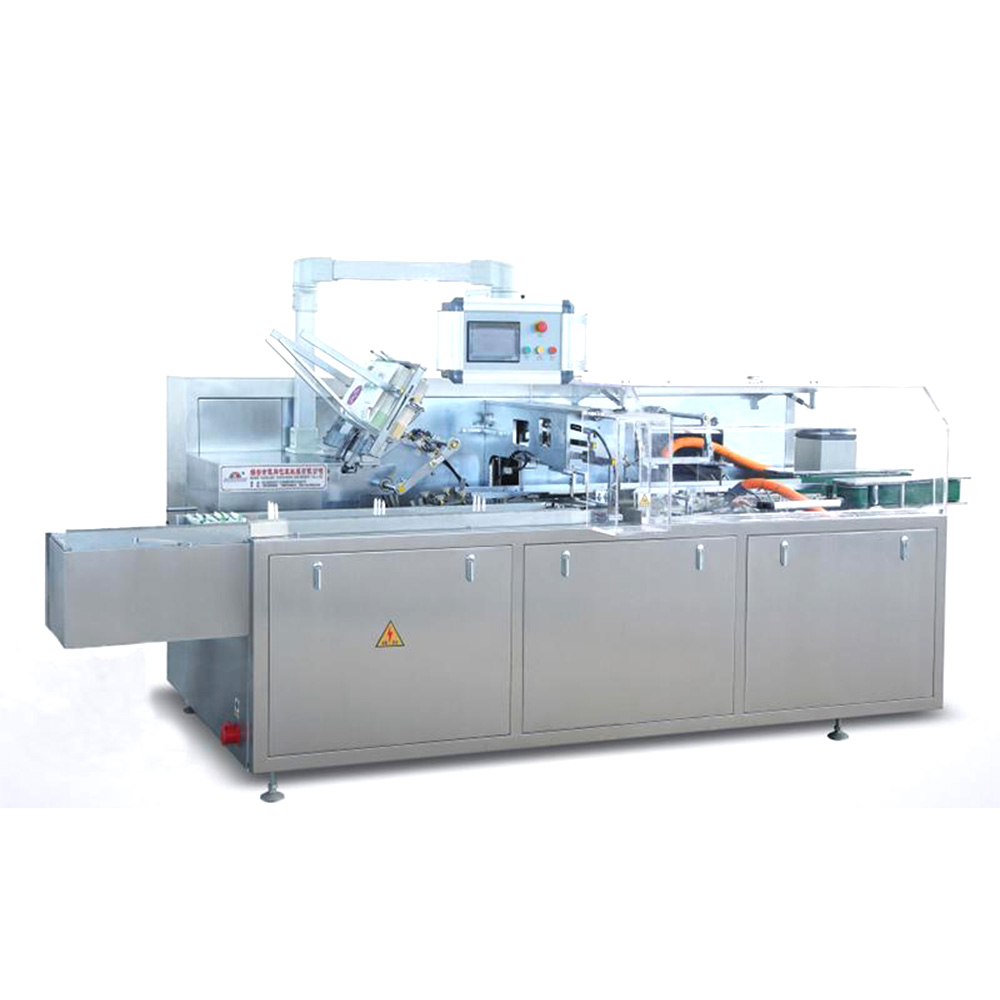

Machine Introduction:

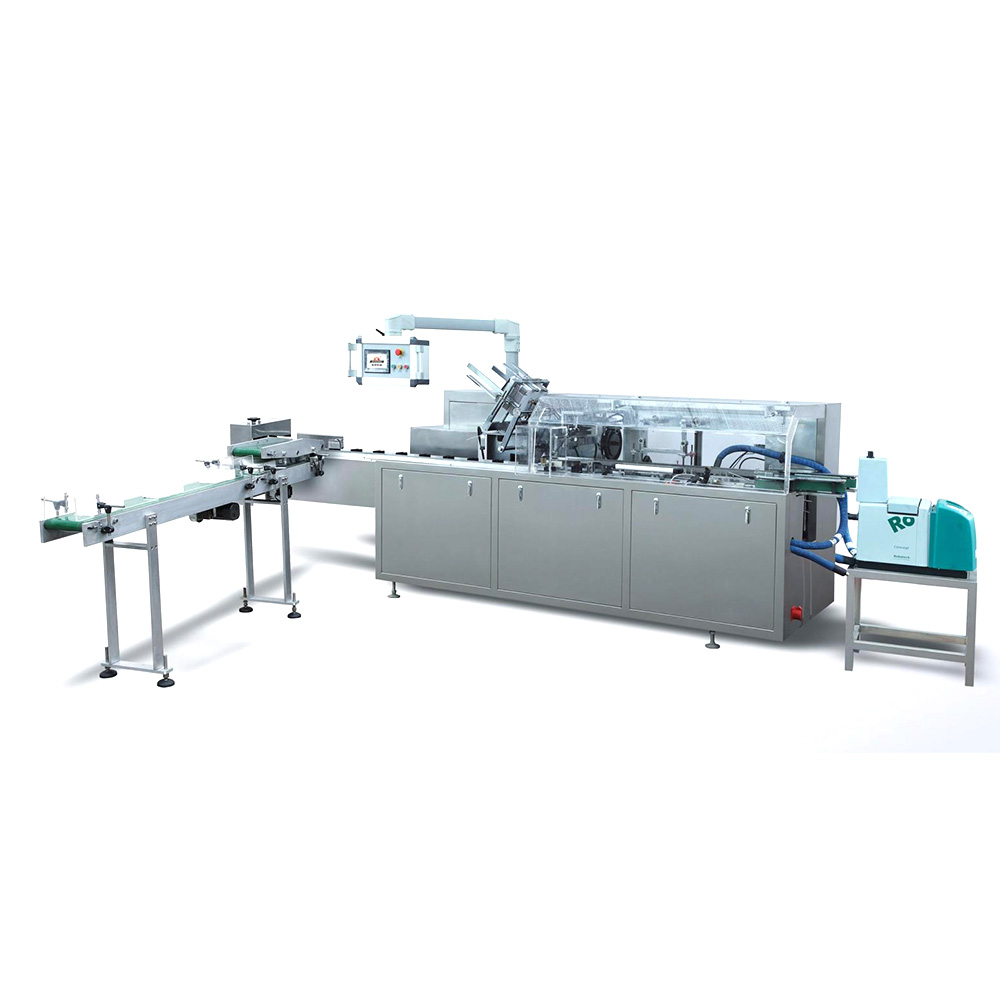

This is packaging cartoner is designed for packages of L (70-350)mm×W(80-200)mm×H(20-90)mm, special sizes can be customized.Can be applied on different sizes such as various medicine, auto parts, food, cosmetics and some other small utensils.

Machine Features:

1.The cartoner is PLC controlled and uses high-quality electrical components from reputable international brands like Omron.

2.It automatically detects the number of items and checks that they are properly placed in the cartons.

3.It avoids wastage by not sucking cartons or spraying glue when there is no material to feed.

4.The machine displays fault alerts, packaging speed, and the number of finished items.

5.The mechanical feeding is stable and precise.

6.The machine can add a material bucket to the conveying belt according to customer needs, and the feeding is synchronized and automated, reducing labor costs.

7.The shell is made of durable stainless steel and aluminum.

8.The electrical components are from a trusted German brand, ensuring stability and durability.

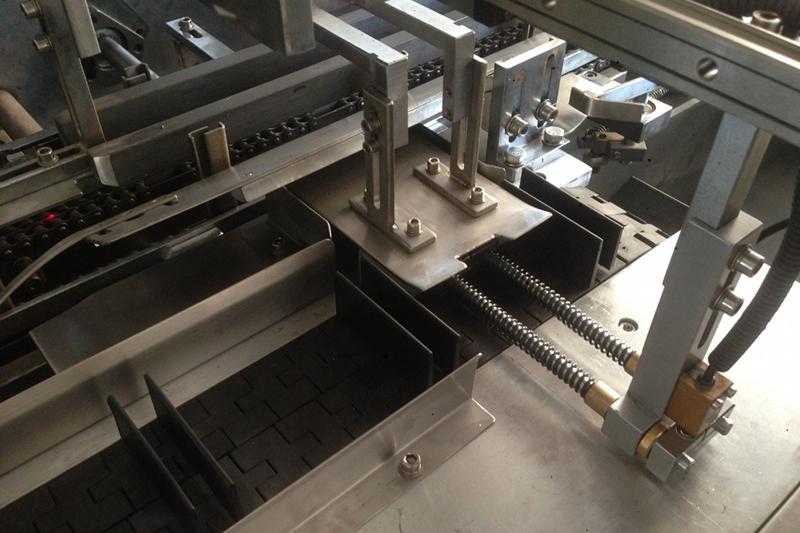

Detailed Pictures: